The Paris Agreement was signed on Earth Day in 2016. Signers of the Agreement committed to reaching net-zero carbon emissions by 2050. With this Agreement in mind, the International Copper Association (ICA) and its members have set goals to reach net zero in Scope 1 and 2 greenhouse gas (GHG) emissions by 2050. Earth Day is a global call to action each Abril 22, and ICA members are answering.

Sustainability at ICA

Since 2011, ICA has conducted a voluntary member survey to collect social, economic and environmental data. All surveyed ICA members have reduction targets and are actively working to decarbonize their operations, reduce waste and reuse water.

Energy Use

Copper production requires significant amounts of electricity, heat and fuel. The industry is actively shifting toward renewable energy to reduce energy use and emissions. Declining ore grades have caused energy intensity rates to gradually increase over time. However, innovations in mining and processing technologies have enabled ICA members to increase productivity and mining efficiencies, extending the lifetime of existing mines. This extension of mine life decreases the energy required for exploration and development of new sites.

innovations in mining and processing technologies have enabled ICA members to increase productivity and mining efficiencies, extending the lifetime of existing mines. This extension of mine life decreases the energy required for exploration and development of new sites.

The majority of GHG emissions come from transportation. Haul trucks, which are used to transport ore and rock, typically weigh around 400 tonnes and consume a large amount of fuel. Many ICA members are working on implementing vehicles with increased fuel efficiency, as well as transitioning to electric fleets, which could cut transportation GHG emissions to zero.

In addition, members are sourcing energy from renewable sources, including solar, wind and hydropower. This enables decreased GHG emissions in the industry even with increasing energy use. While the copper industry is a large energy consumer, copper contributes to a reduction of over 100 million tonnes of GHG emissions per year through its role in green technologies.

Diverting Waste from Landfill

As part of ICA’s member data collection, members reported on the amount of waste generated during the production process and how much was recycled, downcycled or repurposed instead of landfilled. On average, surveyed members diverted over one quarter of their waste from landfill.

For example, recycling HDPE pipes, which are used extensively for moving secondary materials in mine production, is a common practice in circular mining. Downcycling, another circular mining practice, can reduce waste by adding recycled copper scrap from fabrication back into the refining process. Many resources can be recovered during the production process and repurposed for use across industries. This is referred to as industrial symbiosis and can include recovery of iron silicate, a byproduct from processing copper slag, into a marketable product for construction and building materials. This lessens landfilling and reduces GHG emissions for the companies utilizing this product, as production does not require additional energy. To learn more about industrial symbiosis and how it contributes to the circular economy, click here.

For example, recycling HDPE pipes, which are used extensively for moving secondary materials in mine production, is a common practice in circular mining. Downcycling, another circular mining practice, can reduce waste by adding recycled copper scrap from fabrication back into the refining process. Many resources can be recovered during the production process and repurposed for use across industries. This is referred to as industrial symbiosis and can include recovery of iron silicate, a byproduct from processing copper slag, into a marketable product for construction and building materials. This lessens landfilling and reduces GHG emissions for the companies utilizing this product, as production does not require additional energy. To learn more about industrial symbiosis and how it contributes to the circular economy, click here.

Recycling and Reusing Water

The entire copper production process employs water. An increase in water stress poses a potential challenge for the industry. Water does not need to be potable for copper production, but there are limits to the levels of particulate matter in the production process.

The entire copper production process employs water. An increase in water stress poses a potential challenge for the industry. Water does not need to be potable for copper production, but there are limits to the levels of particulate matter in the production process.

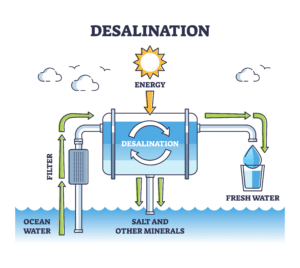

On average, two-thirds of ICA member operational water requirements are met through water recycling. This means only around one-third of the water use comes from outside water sources. Several ICA members utilize desalination techniques on sea water to avoid extraction of valuable freshwater sources; other members leverage treated municipal wastewater. Both techniques are becoming increasingly valuable, especially in water stressed areas. In addition, members are locating efficiencies in their processes to limit the amount of water needed.

ICA members are not only working to reduce water use through water recycling and desalination, but they are acting to provide their communities with access to potable drinking water whenever possible, from capturing rainwater to providing their own technologies to improve and expand access to freshwater. Producing copper responsibly requires a wholistic approach, addressing the key drivers of environmental impact by decreasing energy use and emissions, reducing waste and utilizing natural resources efficiently in cooperation with local communities. As the copper industry works to meet the growing needs of the clean energy transition, ICA members are striving to serve as responsible stewards of both the material and the environment.

technologies to improve and expand access to freshwater. Producing copper responsibly requires a wholistic approach, addressing the key drivers of environmental impact by decreasing energy use and emissions, reducing waste and utilizing natural resources efficiently in cooperation with local communities. As the copper industry works to meet the growing needs of the clean energy transition, ICA members are striving to serve as responsible stewards of both the material and the environment.