To meet growing global ambitions on sustainability, both recycling and primary production will be needed to meet demand, which is expected to double by 2050.

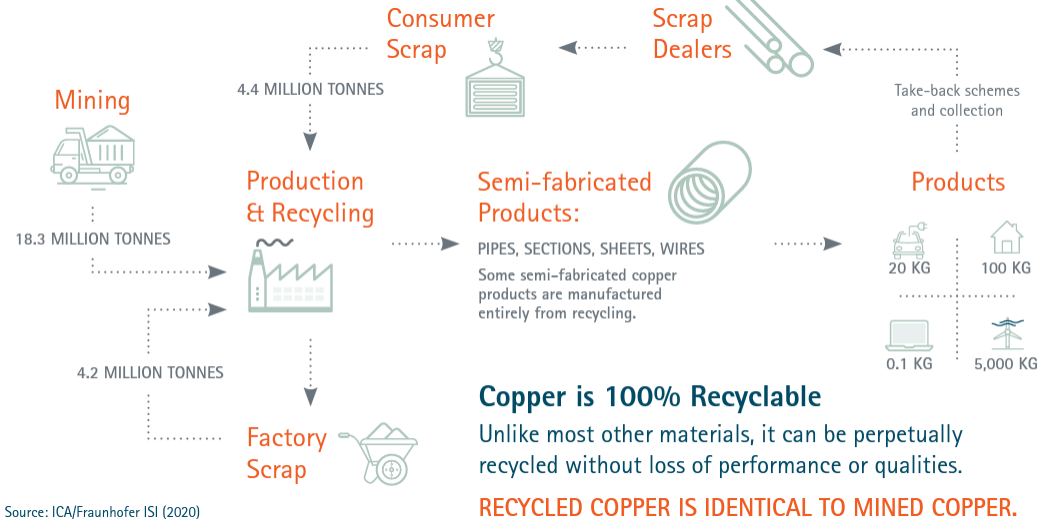

Copper, with its infinite life cycle, is a 100 percent recyclable material that can be used over and over again without any loss of its chemical or physical properties.

A truly circular economy reduces the consumption of natural resources, energy use, waste and greenhouse gas (GHG) emissions by utilizing sustainable and circular materials that maximize the potential of circular systems, which are supported by circular value chains.

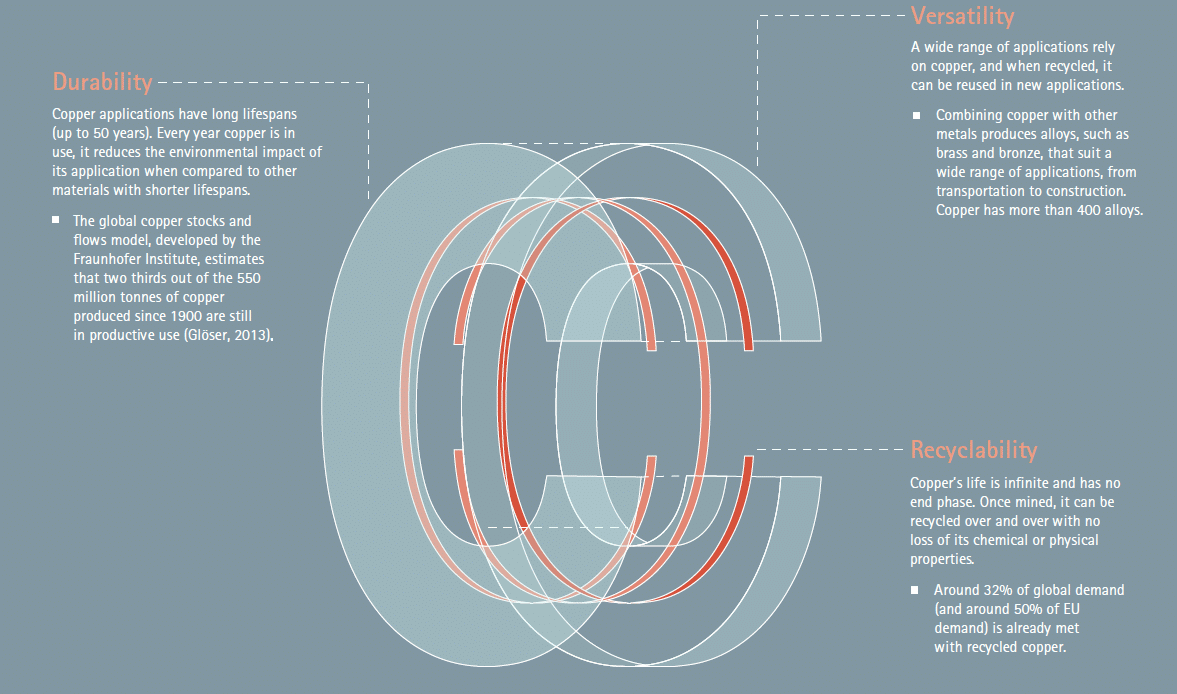

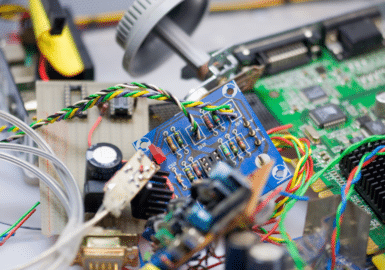

Copper plays a key role in a circular society. As a durable, versatile and infinitely recyclable material, copper provides longevity to a wide range of applications that can be recycled at their end-of-life (EoL) and reintroduced into productive use.

Copper’s applications are drivers of the green transition, enabling renewable energy systems, energy efficiency and sustainable buildings that reduce energy use and carbon emissions. Circular value chains that decrease pollution and waste in pre-consumer operations and post-consumer recycling further lower the environmental impact of copper’s applications.

COPPER IS A CIRCULAR MATERIAL

Copper's natural properties make it ideal for circular applications. Through its ability to be infinitely recycled without any loss of its chemical or physical properties, copper is the material of choice for sustainable and recyclable applications.

COPPER ENABLES CIRCULAR SYSTEMS

important to decarbonization, such as energy storage systems, smart grid technologies and heat pumps, which minimize or eliminate waste and pollution.

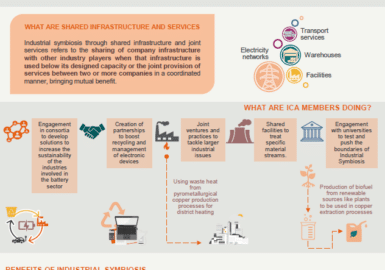

ICA MEMBERS PRACTICE CIRCULARITY

in the production and use of copper, from reducing and reusing natural resources and waste in operations to employing efforts to close the loop for recycling.

ICA members, together with copper value chain, collaborate closely with global policymakers, consumers and NGOs to close the loop on copper recycling.

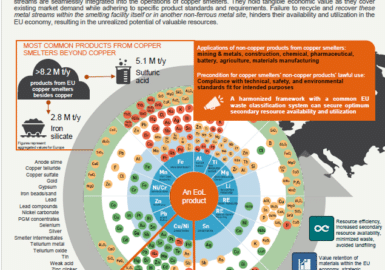

On average, 26.7 million tonnes of copper were used globally each year from 2009 to 2018. During this time, a total of approximately 8.7 million tonnes of copper per year came from the recycling of “old” scrap (i.e., post-consumer copper contained in EoL products) and “new” scrap (i.e., pre-consumer copper scrap generated during production and manufacturing processes).

ICA members are using cutting-edge technologies and innovative recycling processes, such as introducing scrap metals into the smelting process to recycle valuable raw materials and enhance efficiencies. This includes recycling intricate electronic devices and other increasingly complex products.

Did You Know?

Recycling copper requires 85 percent less energy

than primary productionand reduces CO2 emissions.

32 percent of global copper demand

is met with recycled copper.

40 percent of copper is recycled

at product end of life. When pre-consumer scrap is added, this number reaches 56 percent.

ICA Members recycle 4 million tonnes

of post-consumer scrap annually, as of 2018.