For over a decade, the Fraunhofer Institute has monitored global copper stocks and flows. Their copper flow model, created for ICA several years ago, not only provides comprehensive info on stocks and flows but also delivers a copper recycling overview.

Fraunhofer’s work has resulted in a much-improved understanding of how copper is used and reused by society. The full publication Dynamic Analysis of Global Copper Flows. Global Stocks, Postconsumer Material Flows, Recycling Indicators and Uncertainty Evaluation contains additional information.

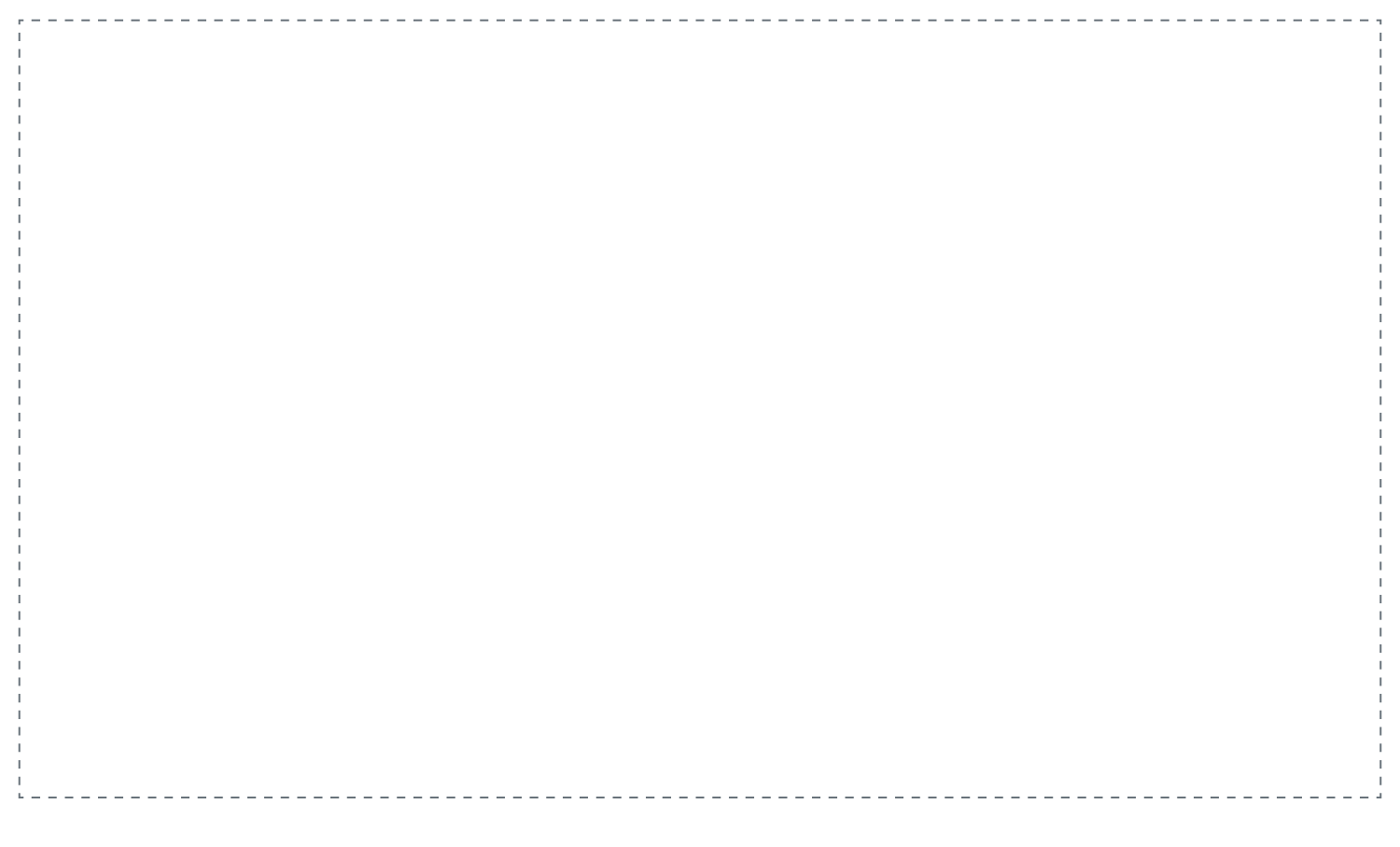

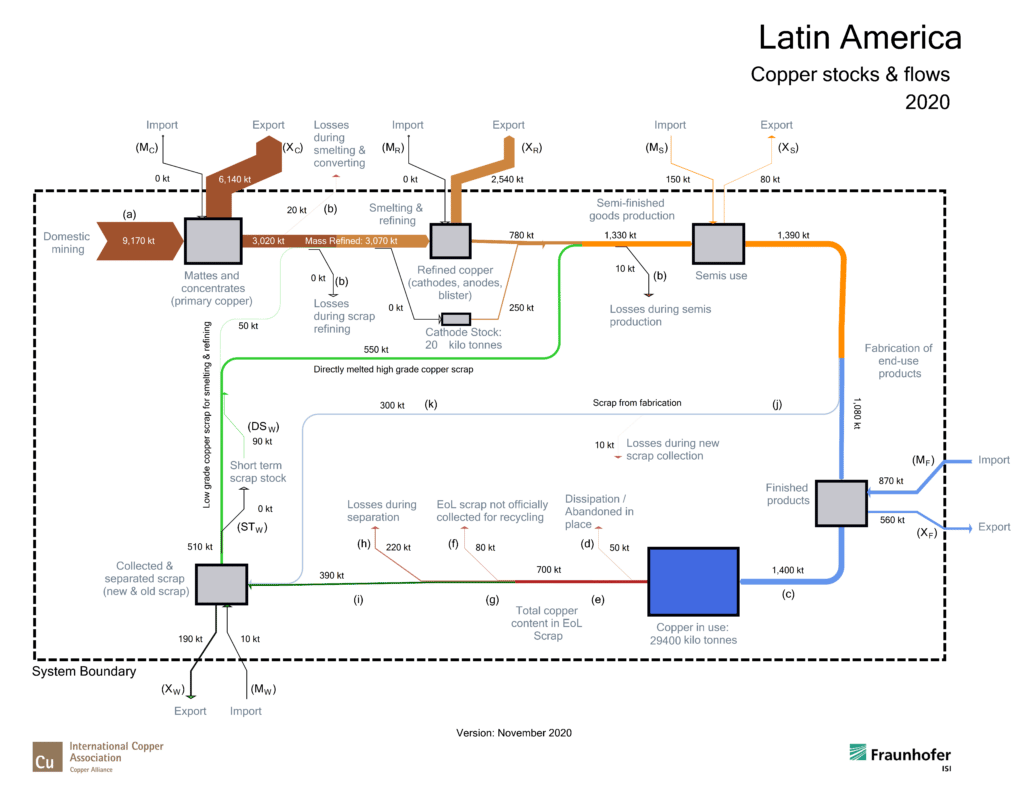

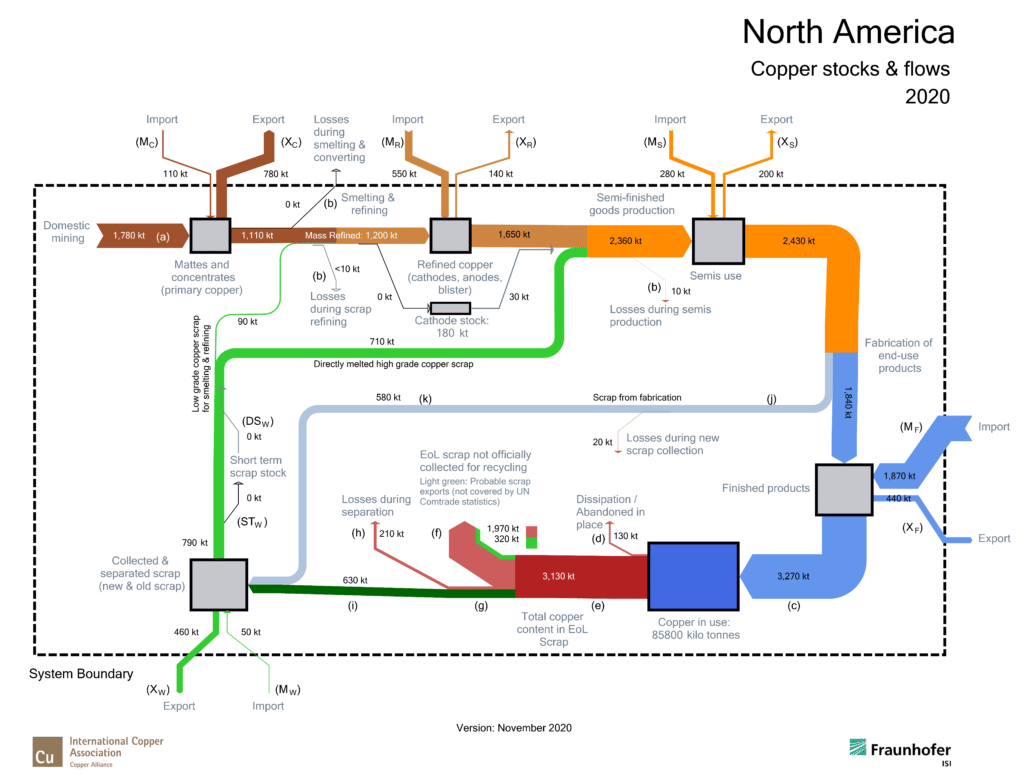

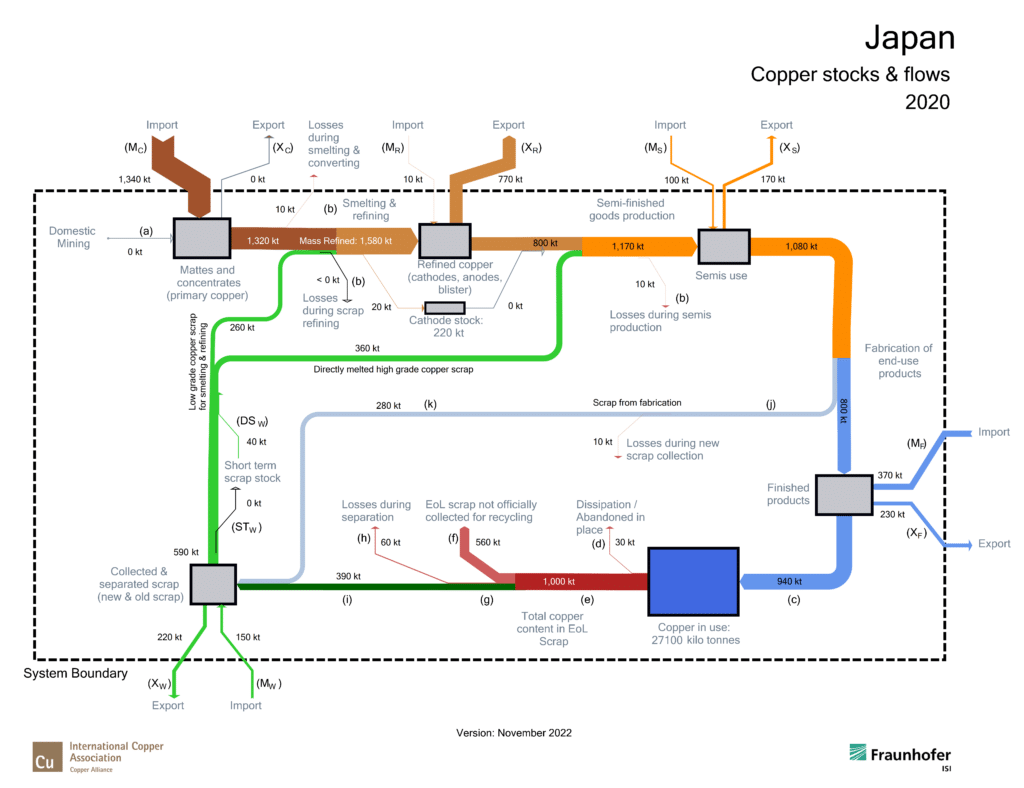

The flow models for the 2020 data year are shown below.

For a description of the methodology, view the following publications:

Close to 21 million tonnes of primary copper were mined in 2020, and almost 28 million tonnes of semi-fabricated products, such as tubes, sheets and wires were produced using a combination of primary (mined) and secondary (recycled) copper. The recycling of scrap from fabrication and end of life products in 2020 contributed to 28 percent of the production of semi-fabricated products. This is the recycling input rate.

See here for a detailed background on the development of the model.

Close to 21 million tonnes of primary copper were mined in 2020, and almost 28 million tonnes of semi-fabricated products, such as tubes, sheets and wires were produced using a combination of primary (mined) and secondary (recycled) copper. The recycling of scrap from fabrication and end of life products in 2020 contributed to 28 percent of the production of semi-fabricated products. This is the recycling input rate.

See here for a detailed background on the development of the model.

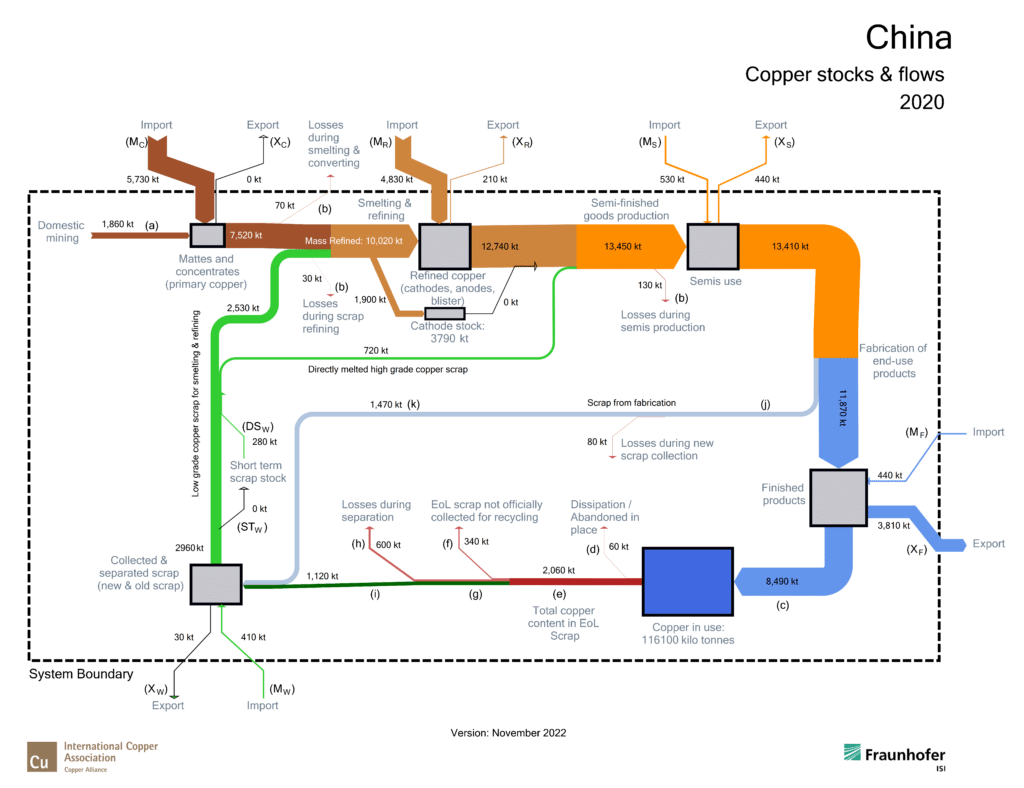

China is the world’s largest producer of copper that is refined, semi-finished and fabricated for end-use products, making it a valuable contributor to the global copper value chain. China produced 11.87 million tonnes of end-use copper products in 2020, and just over 3 million tonnes of copper were recycled.

See here for further analysis of the Chinese copper cycle.

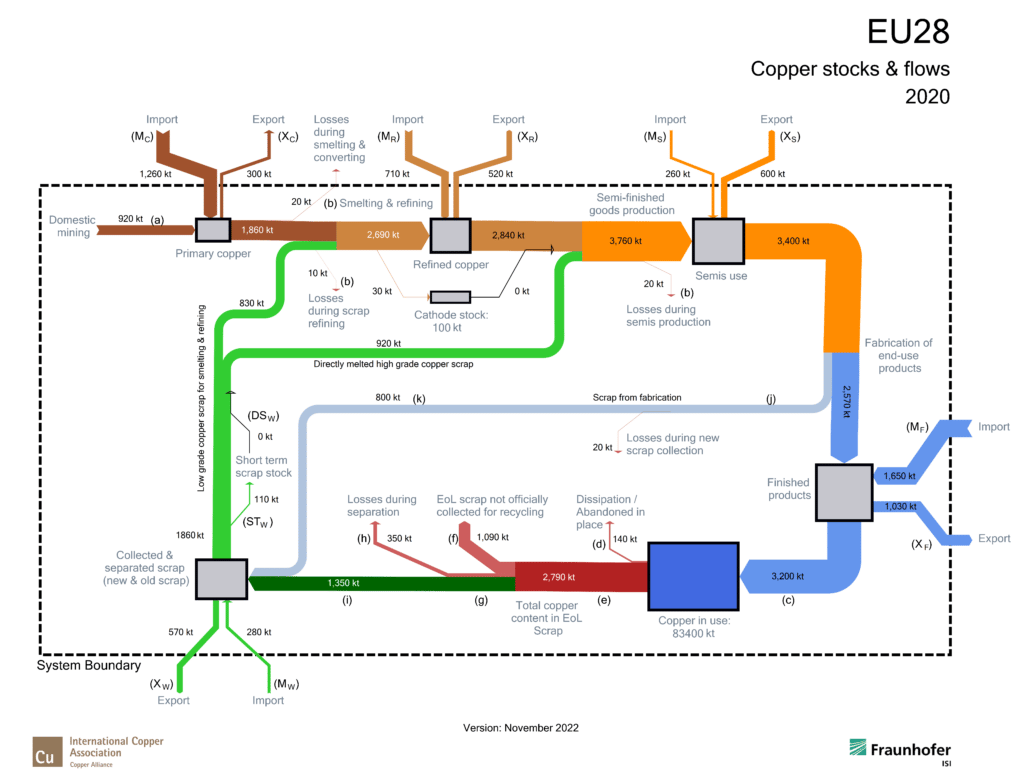

About 83.4 million tonnes of copper are in use in Europe. The copper value chain in Europe is dominated by the production of semi-finished goods and end-use products.

The original publication of the EU28 stocks and flows model can be found here.