About 60 percent of fossil-fuel consumption in India is for road transport. Public buses and two- and three-wheel vehicles used for intracity personal/cargo transport constitute most of this consumption. To alleviate consumption, the government is incentivizing the transition to electric propulsion so 40 percent of two and three wheelers will be electric by 2030. This translates to production of around 200 million vehicles by 2030. However, while there is currently an extensive supply chain devoted to internal combustion (IC) engines, a local supply chain must be developed for widespread implementation of electrical drives, including motors, power controllers and batteries.

Beginning in 2006, the International Copper Association (ICA) worked with the Non-Ferrous Technology Development Centre (NFTDC) in Hyderabad to perfect a low-cost, vertical die-casting process for producing copper rotors for high-efficiency induction motors. Support was provided by ICA, UNDP Global Environment Fund and the Common Fund for Commodities. The target applications were industrial motors, long-small diameter motors for submersible irrigation pumps and motors for electric vehicles. NFTDC fully developed the copper die-casting process and provides training and specialized equipment to Indian manufacturers of copper rotor induction motors

Through interactions with vehicle OEMs about a transition to electric-vehicle production, NFTDC management realized OEMs needed a full drive system solution, not simply a rotor or a full motor. OEMs also needed solutions tailored to the intracity drive cycle—the way traffic creeps along and flows in Indian cities. NFTDC instrumented three-wheel vehicles and buses in cities and analyzed their typical speed and range requirements. Using this information, and with OEM support, NFTDC requested and obtained $6.5 million over five years, 2013 – 2018, from the Indian government to establish the Center of Excellence for xEV Electric Drives, under the National Mission of Electric Mobility, Department of Heavy Industries. NFTDC is at the center of Indian e-mobility developments and has the following capabilities:

- Proven equipment and capacity to manufacture die cast copper motor rotors. The equipment achieves a 13-second cycle time and incorporates a number of innovations including an integrated copper melting and transfer system, highly simplified low-cost tooling, and vertical vacuum-assisted casting to achieve defect-free motor rotors. The locally manufactured equipment can be provided to industry by NFTDC.

- The ability to design, prototype and produce pilot quantities of induction motors and switched reluctance motors as appropriate for two-, three- or four-wheel personal vehicles and buses.

- In-house design, prototyping and test of power electronics controllers for motors using the latest software development and electronics system production techniques.

- Integrated motor/controller test facilities to confirm systems meeting the drive-cycle requirements.

The Center of Excellence for xEV Electric Drives is a unique facility in India. In one place, by one integrated multi-disciplinary team, an OEM can get a pre-production prototype drive system optimized for a particular vehicle and drive cycle. The team designs optimized components, fabricates the components, assembles them into a system, and tests the system performance versus specifications. The Center of Excellence will speed the use of copper in electric vehicles produced in India.

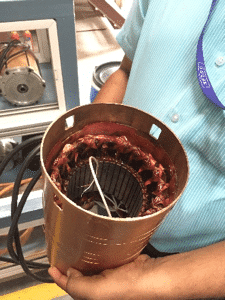

- Prototype motor fully designed and fabricated at NFTDC. The motor has a high strength, thin wall (1.5mm) copper case that is lighter than an aluminum case

- Typical three-wheel vehicle

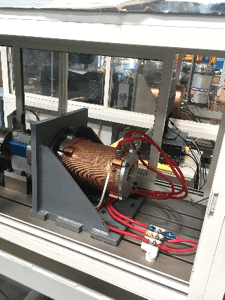

- Bus motor under test

NFTDC is working with two industry consortia to transfer this technology into use in India. One consortium involves the major electric-motor manufacturers; the other involves the full automotive supply chain.

The NFTDC EV Electric Drives team of about 40 persons has the necessary infrastructure, capability and engagements needed to accelerate the introduction of electrical drive systems into widespread use in India. The innovation of every aspect of electric drives makes them particularly appropriate for e-mobility in Indian cities. ICA’s early action to transfer energy-efficient motor technology into India is expected to have a large impact on decarbonizing mobility.