Growing electric vehicle (EV) demand has often gone hand-in-hand with growth in demand for copper. However, it is only more recently that it has been possible to estimate just how much this demand will increase, and what’s driving it.

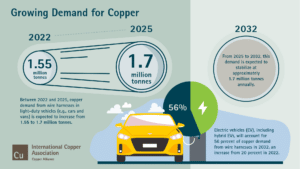

New research, commissioned by the International Copper Association (ICA) and conducted by the Martec Group, has revealed that demand for copper in the wire harness in the light-duty automotive industry is expected to grow to more than 1.7 million tonnes annually by 2032. Simultaneously, overall copper demand related to EVs is expected to grow by 36 percent.

As the automotive industry increasingly shifts focus toward the electrification and automation of vehicles, with the overarching goal of decarbonizing transport and facilitating sustainable development, fuel economy regulation, weight reduction and miniaturization are also expected to drive increased demand for copper in favor of aluminum and other substitutes.

What’s driving copper-based motors and EV technology

A typical vehicle with a standard internal combustion engine (ICE) has an estimated 23kg (51lb) of copper. When ICEs are compared to EVs, we find that an EV will have roughly three to four times more copper, which is mostly used in the copper rotor induction motor. But why is this? Copper has many applications in EVs, including wiring looms, winding wire (motors), energy storage (foil and busbars in batteries) and power cables. As a result of its naturally high conductivity, copper is the ideal material for the high-speed data wires needed in vision systems and sensors. Looking ahead to 2040, the research commissioned by ICA predicts that, among a wide range of components, the wiring loom alone will account for more than 50 percent of copper demand for EVs.

EV manufacturers have traditionally relied on rare earth metals for motors, but these metals have faced increasing availability and sustainability challenges, causing EV manufacturers to innovate. Offering greater reliability and sustainability than rare earth metals, copper has become the material of choice to increase energy efficiency in EVs due to its conductive properties. As a result, copper is and will continue to be a key enabler of the rollout of EVs across the globe, and in turn, the decarbonization of the transport industry.

Copper underpins EV charging networks

EVs aren’t the only drivers for copper demand in the automotive industry. Adoption of EVs globally will require a network of charging infrastructure. SAI Industrial LLC predicts the number of EV charging ports will grow from 3.2 million in 2021 to 152.3 million in 2040. This growing number of charging ports is expected to result in an additional 978,000 tonnes of copper being needed to meet demand for charging infrastructure in 2040, a dramatic increase from the 43,300 tonnes used for charging ports 2021.

Copper’s popularity for charging ports and stations is largely due to its natural electrical conductivity and durability. The metal’s role in EV infrastructure also includes power cabling and heavy equipment, such as transformers and utility grid upgrades.

The exciting move to autonomous vehicles

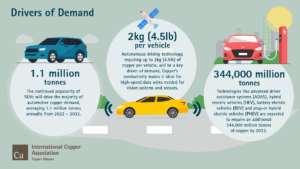

Beyond electrification, advances in vehicle technology are leading to increased automation. Vehicle automation requires multiple sensors, as well as additional on-board computers. A standard autonomous system, with 12 cameras, seven Light Detection and Ranging sensors (LiDARs), eight radars and one automated driving control unit, will all depend on copper connections to function safely and reliably. Each sensor and computer contain printed circuit boards, which require approximately 50 – 100g of copper depending on the board’s size.

However, when automation and electrification are combined, the amount of copper required for vehicle production further increases. Autonomous BEVs, for example, will require more than double the copper needed for electronics when compared to the conventional internal combustion vehicle. As the number of fully or semiautonomous vehicles on the road increases, so too will demand for copper components.

What’s next

In total, depending on technological developments, the EV of the future may contain as much as 72kg

(159lb) of copper—significantly more than the copper used currently in an ICE vehicle. This trend demonstrates the importance of copper as a sustainable alternative to the rare earth metals that have traditionally been popular with vehicle manufacturers.

Copper’s place in the global rollout of EVs, autonomous EVs and charging infrastructure will continue to contribute to sustainable development, decarbonization and the global green transition goals—long into the future.

Find out more

- IDTechEx – The Electric Vehicle Market and Copper Demand

- SAI Industrial – Power Cables in New and Emerging Markets

- Martec Group – Automotive Wire Harness Market Assessment 2022

About the International Copper Association

The International Copper Association (ICA) brings together the global copper industry to develop and defend markets for copper and make a positive contribution to the UN’s Sustainable Development Goals. Headquartered in Washington, D.C., ICA has offices in three primary regions: Asia, Europe and North America. ICA and its Copper Alliance®️ partners are active in more than 60 countries worldwide. For additional information, please visit www.copperalliance.org.