Cutting, welding and additive manufacturing of metals using lasers has made tremendous advances, saving time, improving quality and reducing material use for manufacturers in industries ranging from lithium ion batteries to smartphones and aircraft. However, using laser light with copper has been very difficult because of copper’s high thermal conductivity and reflectivity. Copper only absorbs 5 percent of typical infrared laser light, and this absorbed heat energy diffuses rapidly, inhibiting the melting necessary to cut and join copper and to join copper to other metals. Using higher power to overcome the thermal conductivity leads to spattering, porosity and poor weld performance. Newly available high power blue laser light (with a wavelength of 450 nanometers from gallium nitride laser diodes) is highly absorbed by copper and can be focused on a tiny spot, allowing copper components to be joined quickly. In addition, additive manufacturing using copper and copper-alloy powders can take a huge step forward in speed and quality.

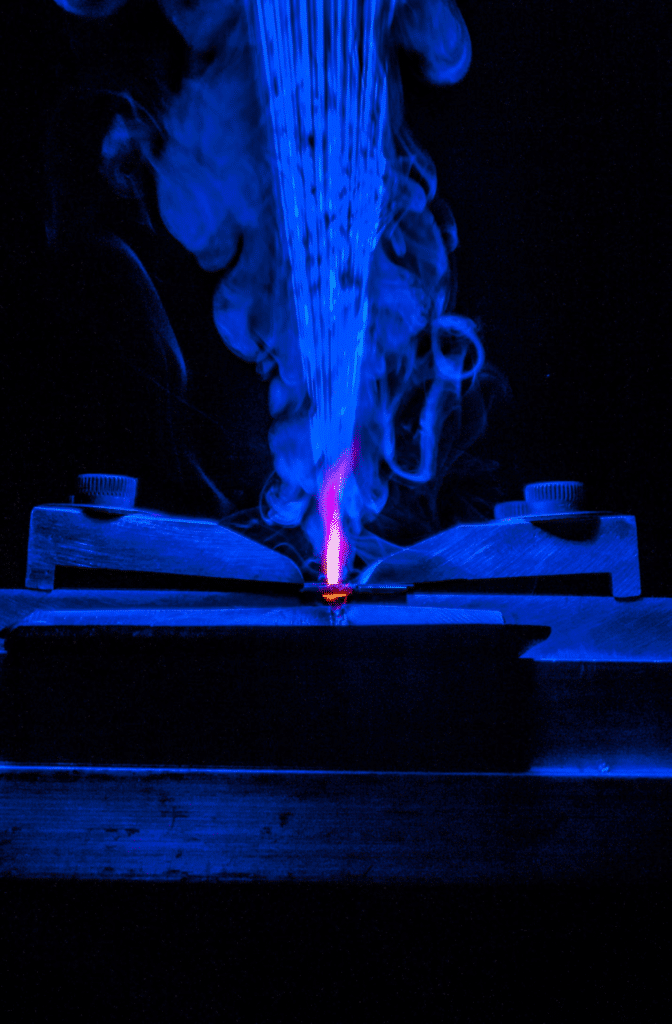

Photo courtesy of NUBURU

Start-up technology company NUBURU makes a high-power blue laser. Company co-founders Mark Zediker and Jean-Michel Pelaprat are laser physics innovators. They took on the challenge of enabling copper welding in 2014 to overcome the drawbacks of infrared laser and ultrasonic welding, with a particular focus on advanced batteries. Very thin copper foil is used in these batteries, and many layers of foil must be welded together to provide a conductive path for electric current. With a growing market in electromobility, manufacturers need to make larger quantities of batteries faster and more efficiently. A 150 Watt blue laser can perfectly weld copper foils and leads used in a lithium ion battery. This is like stacking 40 sheets of thin kitchen foil and then welding the layers together in an instant. A 500 Watt model will be available soon, with the ability to weld foil even faster to keep up with the production demands of battery and smartphone manufacturers. Welding copper with a blue laser also eliminates the need for solder and avoids creating tiny particles that can cause shorts in batteries.

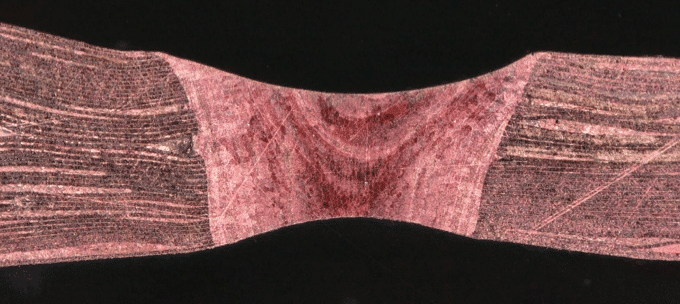

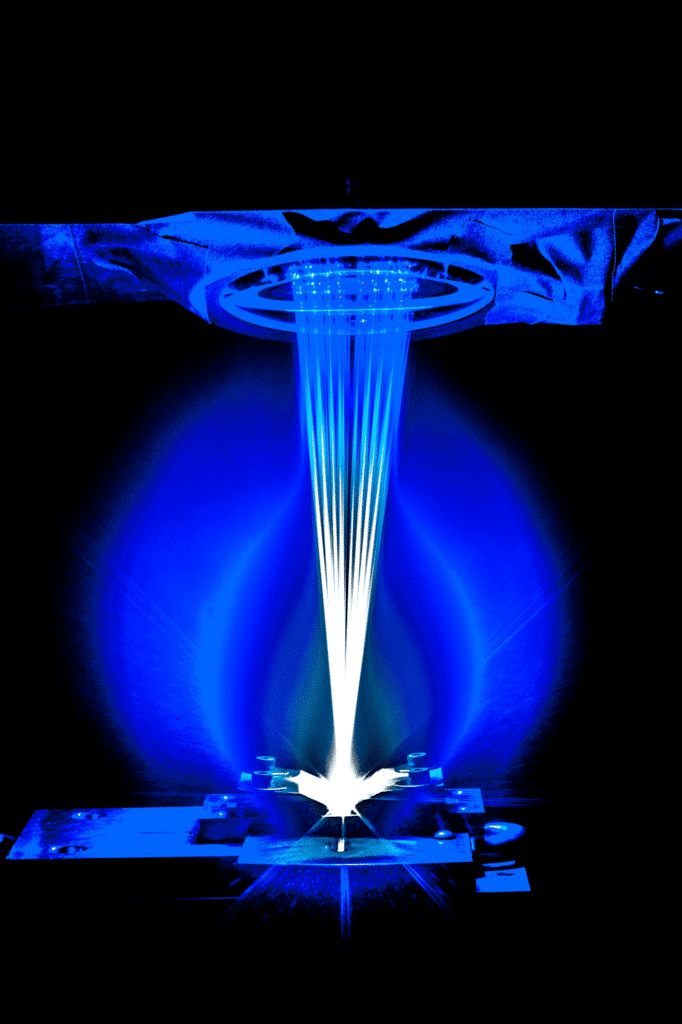

Start-up company Formalloy uses the blown powder technique for additive manufacturing and is the first company to integrate the blue laser into an additive manufacturing system. In this approach, metal powder is continuously conveyed into a laser focus by an inert gas. The laser melts the metal powder, which then continuously impinges on a surface. Careful control permits the system to build metal parts. Metal powders can also be mixed to create alloys. For example, a blend of copper and nickel can be made, with 100 percent copper on one side, 100 percent nickel on the other, and a grading from one metal to the other in the middle. NASA is interested in this new capability for building rocket nozzles, and it also works well for many electrical applications.

This pioneering blue laser light technology is highly complementary to the growing demand for copper in technically advanced products such as batteries for electric cars, personal electronics, aerospace components and the next waves of future innovation.

Photo courtesy of NUBURU