Responsible resource stewardship is essential to the future of modern development in a climate-conscious society.

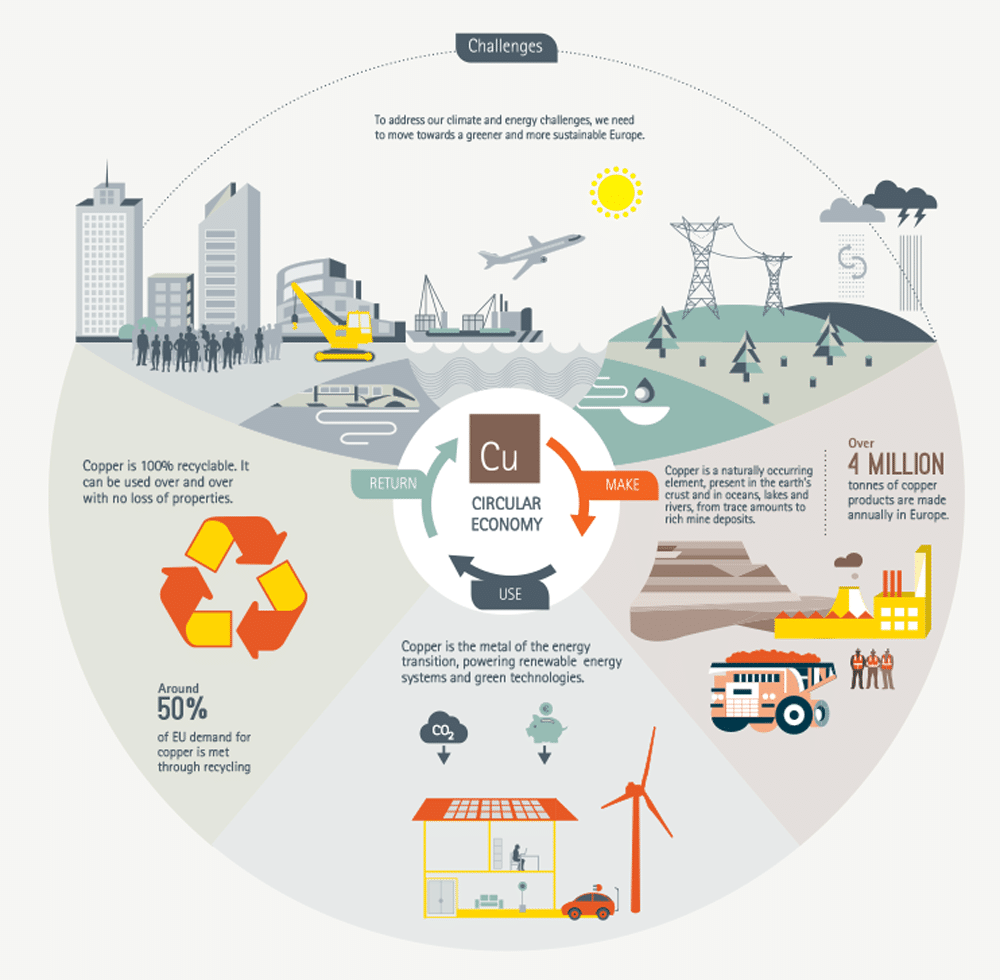

The circular economy can help meet demand for raw materials and lessen environmental impact by reducing and reusing waste.

A central theme of the circular economy concept is the valuation of materials within closed-loop systems. The optimal use of resources has been identified as a tool that can supplement the European Union's low-carbon strategy and can boost markets and the economy. This requires maximizing the potential value of materials by developing closed-loop systems of recovery and reuse. An essential prerequisite for these systems is the decoupling of economic growth from resource use in the context of a broader systemic change for producers and consumers.

Copper is a truly circular material that can be recycled without any loss of properties, making it a strategic material of choice and the copper industry an enabler of circularity and resource efficiency.

Featured Resources

Copper: a Circular Material

Table of Contents

EU Industrial Strategy

At the heart of the European Green Deal is the new EU Industrial Strategy, which presents a plan for an ecological and digital "twin transition” in EU industry while ensuring competitiveness via-à-vis the rest of the world. Energy-intensive industries are required to reduce their carbon and material footprint. Recycled copper already serves as a sustainable avenue to a) meet the increasing demand for copper, being a carrier metal, in products of key value chains and b) secure clean and affordable energy. Promoting circular practices will reinforce the global competitiveness of the copper industry through its multifaceted integration in international value chains.

The twin transition needs to be both just and sustainable. Partnerships that leverage industry expertise and increased EU participation in international standardization bodies are essential to developing or harmonizing standards and technical regulations. According to the EU Industrial Strategy, priority will be given to high-impact product groups to promote investment in innovation and scalable market strategies. To this end, the copper industry is and shall remain a frontrunner in developing products that adhere to the EU's ambition for a green, digital and resilient industry, in line with the European Green Deal and the Paris Agreement aspirations.

Circular Economy Action Plan (CEAP - 2.0)

The Circular Economy Action Plan (CEAP 2.0) aims to make sustainable products the norm on the EU market. It focuses on resource-intensive value chains with high circularity potential, such as electronics, batteries, vehicles, construction and buildings. The Action Plan strives to reduce waste through effective resource management, extending material usage and providing their subsequent reuse in new products.

The copper industry is focused on ensuring a safe and sustainable operating space for the realization of a truly functional circular economy. Copper’s natural properties make it a key material in the green transition. To achieve the EU’s electrification and decarbonization strategies, both primary and secondary copper production will be needed to meet demand. To this end, promoting life cycle thinking, optimizing product and system design, and maintaining responsible and ethical copper production are at the forefront of the copper industry’s circularity efforts.

ECI supports the establishment of appropriate recycling efficiency indicators that demonstrate the efficacy of the waste management system, taking account of sector-specific nuances. Simultaneously, circular systems that maximize the use of industrial by-products (“industrial residues”) and promote recycling of existing materials (“in-stock”) need to be incentivized to reach the full potential of material use for the environment and the economy.

In doing so, the viability and limitations of recycling processes and strategies must be considered. If systems try to maximize resource conservation by increasing recycling processes beyond technically feasible levels, it will lead to an overconsumption of energy. These considerations can be addressed through state-of-the-art technologies, but these technologies would need to be deployed on a larger scale.

Recycling goes beyond just solid materials. Management of chemicals, which should be based on the chemical’s risk assessment and societal value, is also key to developing circular systems.

Eco-design for Sustainable Products Regulation

The initiative’s Design-for-Sustainability approach will prioritize product groups to set up eco-design performance and information requirements. In doing so, sectoral specificities will determine the criteria for products, including inter alia resource use and resource efficiency, substances of concern that negatively affect re-use and recycling of the products in scope, energy consumption from cradle-to-gate, and environmental impacts resulting from the products’ lifecycle. It will also consider systemic opportunities and solutions. For example, sustainable building design, when addressed holistically, can save energy at equivalent rates to expected savings from policies addressing product efficiency alone. In addition, fostering industrial symbiosis by increasing the use of circular materials can contribute to product sustainability. Consumers are important actors in perpetuating sustainable systems through their market choices, and sufficient incentives should not be overlooked.

Green Claims Directive

Recognition of voluntary initiatives and schemes remains of paramount importance if Europe wants to leverage the benefits of these environmental performance improvements. The criteria for the recognition of schemes shall be harmonised across all EU legislation, including the Green Claims Directive.

Waste Framework Directive

In view of the Circular Economy Action Plan's ambition to avoid and reduce waste, the European Commission is expected to set targets for reduction in specific waste streams and for waste prevention. Managing waste in an environmentally sound manner and maintaining the value of secondary materials are essential steps toward waste reduction. Today's Waste Framework Directive is the EU's legal framework for treating and managing waste in the EU. It introduces an order of preference for waste management called "waste hierarchy". Copper's value incentivises the recycling of End-of-Life (EoL) products, such as electric and electronic equipment. In 2021, the International Copper Study Group estimated that 33 per cent of global copper use came from recycled copper, while the 2020 EoL copper recycling rate in Europe reached 53 per cent.

In addition to EoL products, industrial residues, or "engineered minerals" generated during the copper smelting and refining processes (e.g., iron silicate), also contribute to the circular economy. When these by-products are not landfilled but given new applications, they can bring significant environmental and socio-economic benefits while reducing waste. ECI also supports waste minimisation through “urban mining”. Materials in use today, known as "anthropogenic stock", are tomorrow's secondary resources for new products.

Batteries Regulation

ECI welcomes the initiative of the European Commission to revise the Batteries Directive and minimise the harmful effects of battery production pollution. Rules from the Batteries and Waste Batteries Regulation cover rechargeable industrial and electric vehicle (EV) batteries' full life cycle, ensuring that all batteries are produced in a sustainable manner. ECI supports an increase in investment in the development of better collection, dismantling and sorting technologies, allowing for more cross-industrial cooperation. This will boost the Commission's efforts to reduce landfilling and help with market incentives for increasing recycling rates.

Waste from Electrical & Electronic Equipment Directive

ECI welcomes the intention of the European Commission to evaluate the progress made under the Waste from Electrical & Electronic Equipment Directive (WEEED). With WEEE representing the fastest-growing source of waste in the EU, it is timely that the Commission aims to secure environmental and human health protection, sustainable production and consumption, and the efficient use of resources in the WEEE value chains. Nearly 70 percent of copper produced is used for electrical/conductivity applications and communications. ECI, acting as steward of copper material within WEEE, wishes to deliver on the ambition to reduce e-waste generation, encourage collection, reuse and recycling of electrical and electronic products, and recover the copper embedded in these products.

E-waste management is confronted with two big challenges. The former challenge is linked to the exports of WEEE to third countries with laxer environmental and safety standards or the exports of WEEE as second-hand to circumvent controls. This, in conjunction with a fragmented reporting framework, creates problems in e-waste management and the completeness of EU statistics. The latter challenge pertains to the unavoidable CO2 emissions linked to recycling processes that aspire to push more ambitiously resource efficiency (e.g., burning of complex plastic). For this, trade-off considerations shall be put upfront in policymakers’ agendas to avoid the realisation of one policy area’s objectives (e.g., recycling efficiency) hijacking the efficiency of another (e.g., energy efficiency). The copper industry is invested in identifying the hotspots for recycling inefficiencies and collaborating with other actors across the supply chain to guarantee proper collection and responsible e-waste management.

End-of-Life Vehicles Regulation

The European Commission has set a clear goal to ensure that End-of-Life Vehicles (ELVs) are managed sustainably. The revision of EU rules will establish measures to improve the collection, treatment, and recycling of ELVs, and encourage the car industry to adopt a sustainable model for the design and production of cars. Copper demand in vehicles is expected to grow rapidly over the next years. For example, copper’s role in the future of electric vehicles is broad, touching various components, including vehicle wiring looms, energy storage, and power cables. For battery electric vehicles, more concretely, these will require up to three times more copper than an internal combustion engine vehicle.

Copper producers’ goal in this context is to recover the maximum amount of copper out of ELVs, thereby maintaining its value within the economy for as long as possible. ECI wishes to ensure that appropriate recyclability targets are set for copper in ELVs. At the same time, any information requirements in vehicle product passports shall not duplicate with other product passports, such as the digital product passport stipulated in the Eco-design for Sustainable Products Regulation. Other measures, such as better implementation of Extended Producer Responsibility (EPR) schemes, controls of exports, or rules about shredding and removal of components, all aim at tackling the issue of unknown whereabouts and further closing the loop within the vehicles’ value chains.

Authored By

Aurelio Braconi

Director (EU),

Material Stewardship

Symeon Christofyllidis

Regulatory Affairs Specialist