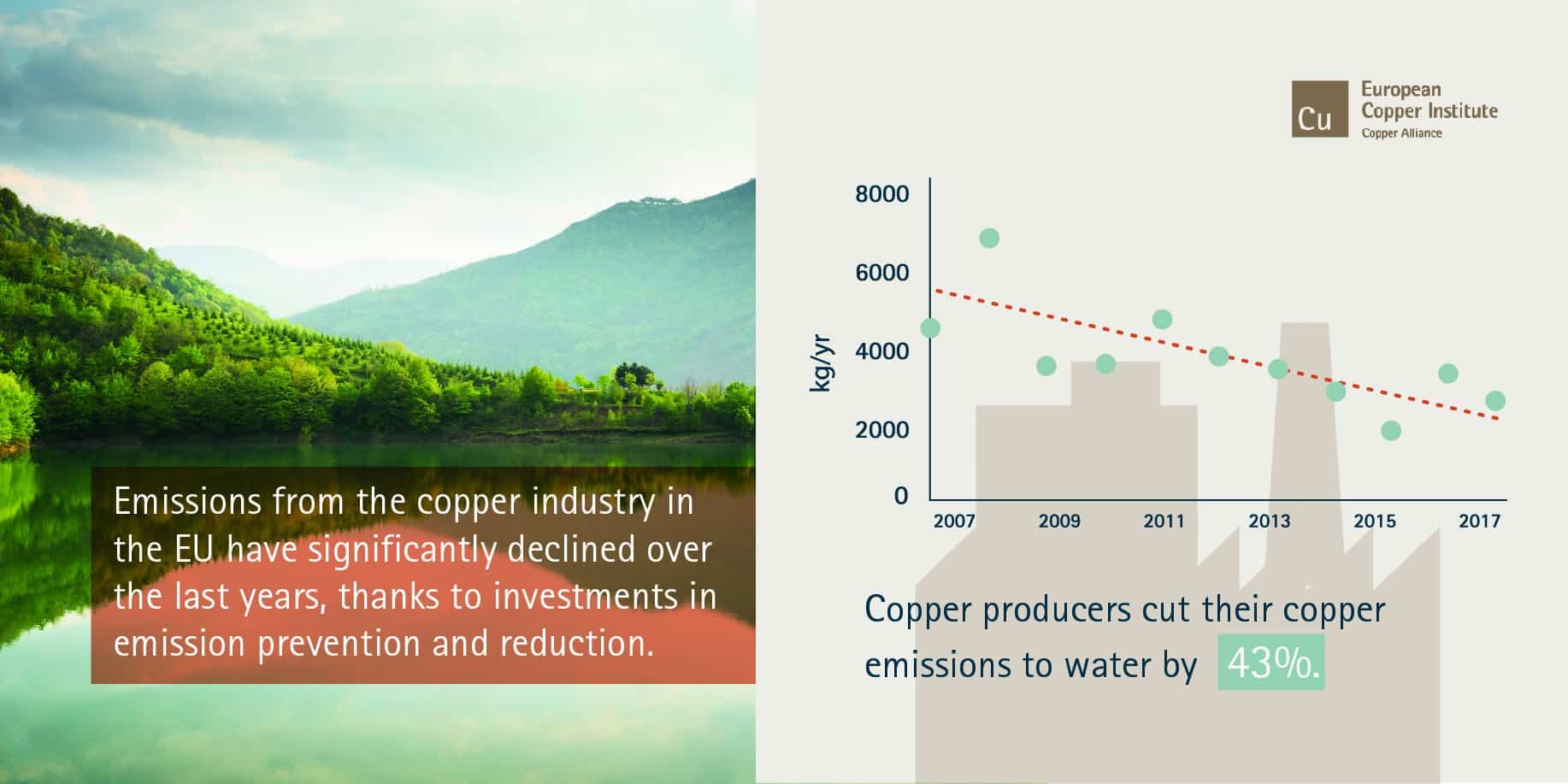

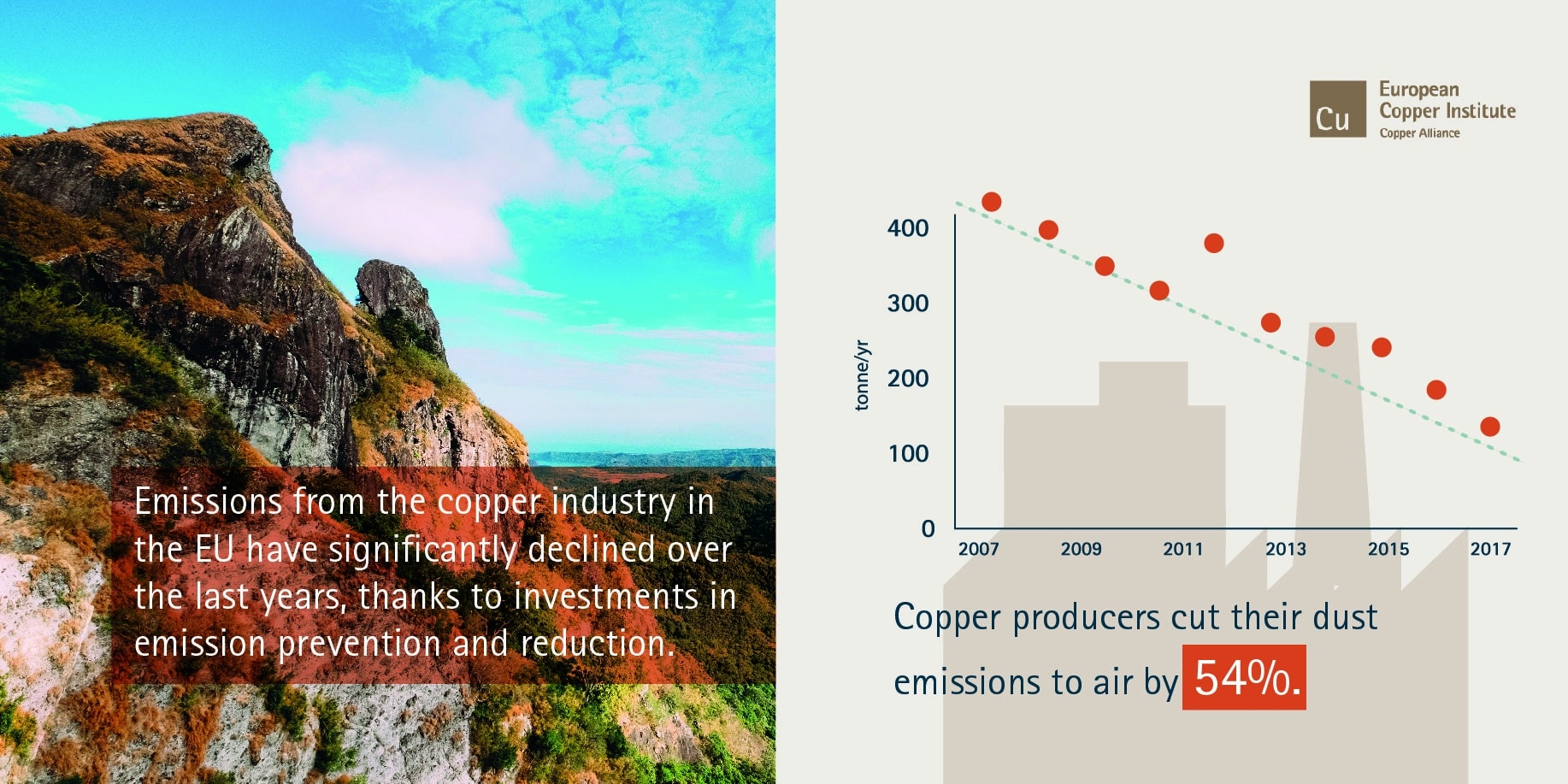

Emissions from the European copper industry are on a downward trend.

The European copper industry is very conscious of the impact that its operations have on the environment.

The Industrial Emissions Directive (IED) regulates pollutant emissions from industrial installations. It aims to protect humans and the environment by reducing industrial emissions. The European Copper Institute supports the objectives of the IED, and has actively contributed to the development of the Best Available Techniques (BAT) reference document for the nonferrous metals sector. The IED is a success: it has ensured that the European copper industry significantly cut its emissions over the past decade. For example, the emissions of copper to water, and the emissions of dust to air, have halved since 2008. In the context of the evaluation of the IED, the European Copper Institute has issued a position paper where these trends are further documented.

Water treatment: case studies

With water being one of the natural resources used to produce copper, the European copper industry has invested significantly in on-site treatment facilities in order to ensure that discharges are safe and compliant with local permits.

Industrial water is used in the copper industry for a variety of purposes including indirect and direct cooling, slag granulation and electrolysis. Treatment processes ensure that all waste water is treated and that dissolved metals and solids are removed. Some of the treated water is reused, thereby reducing the consumption of fresh water. This offers further benefits in terms of environmental protection and resource efficiency.

One side-effect of the copper industry’s wastewater treatment processes is the generation of by-products that can be used by other industries. Gypsum, for instance, is used in plaster-board manufacturing and in the cement industry.

The EU has an extensive legal framework in place to protect water bodies, as well as to ensure that industrial waste water complies with comprehensive limit values prior to discharge back into the environment. This includes the Water Framework Directive, Environmental Quality Standards, REACH, Industrial Emissions Directive etc.

The links from this section highlight three examples which illustrate how the European copper industry has developed treatment processes both to minimise the amount of wastewater and to ensure it meets the required quality standards before it is redirected to streams, rivers and coastal waters:

Poland

KGHM commissioned a €1.8 million upgrade to the wastewater treatment facility at its Cedynia copper wire rod plant in Poland and, as a result of this modernisation investment, wastewater that meets the EU stringent requirements can be safely discharged into the Odra River.

Bulgaria

Aurubis, Europe’s #1 copper producer, opened a €6.3 million rainwater treatment plant at its Pirdop production facility in Bulgaria and became one of the few in the EU to combine three treatment facilities (for industrial, domestic and rainwater).

Germany

Through the progressive installation and use of several closed-circuit cooling systems, KME Osnabrück in Germany can now reuse the same water up to 16 times and has reduced its wastewater discharges from around 1 million down to around 50,000 m3/year.