The copper industry is committed to providing data and information to enable users of copper to evaluate its impacts and benefits across the life cycle.

As part of our commitment to sustainability, and to help our members improve their own processes, ICA has gathered information and data to enable the users of copper to evaluate its impact and benefits across the life cycle.

Part of this work is the Copper Environmental Profile, which features the results of ICA’s copper cathode Life cycle Assessment (LCA), the most representative and comprehensive industry global data set on copper cathode and concentrate to be made publicly available to date.

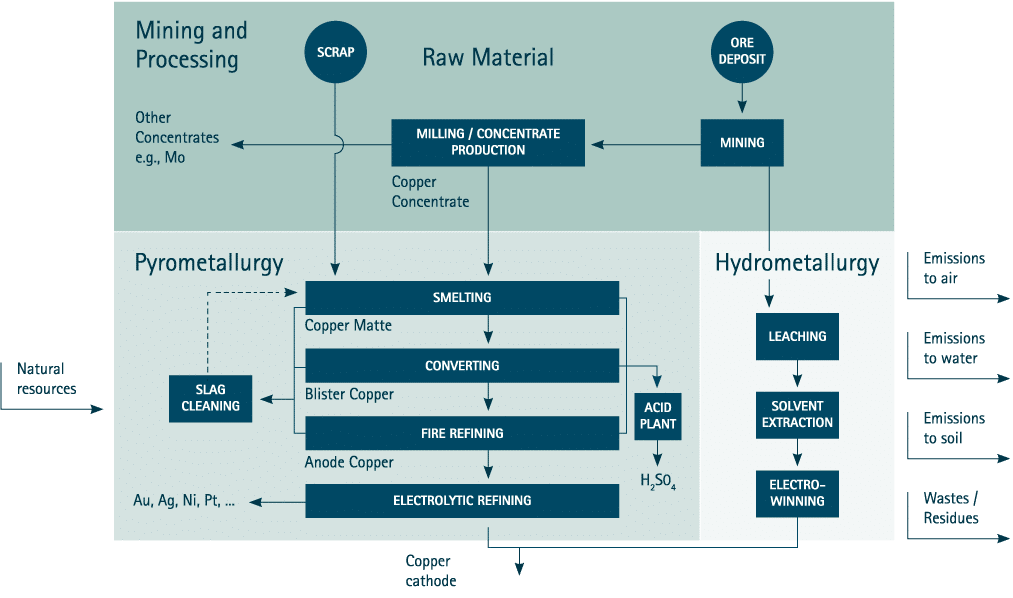

The International Copper Association’s Copper Cathode Life Cycle Inventory (LCI) provides critical environmental information from mining to smelting and refining and, therefore, serves as an important foundation for full product life cycle studies. As with any material, the potential environmental impacts of copper are best understood by taking a full life cycle perspective e.g., when used as copper wire, copper’s electrical conductivity can improve the energy efficiency of energy-using products, making those products more sustainable during the use phase.

8.5 million tonnes

Amount of copper that comes from recycling each year.

More than 30 percent

Amount of copper originating from recycled sources over the last decade.

80 - 90 percent

Reduction in energy required for recycling copper, which is equivalent to taking 16 million passenger cars off the road.

Copper’s Environmental Profile

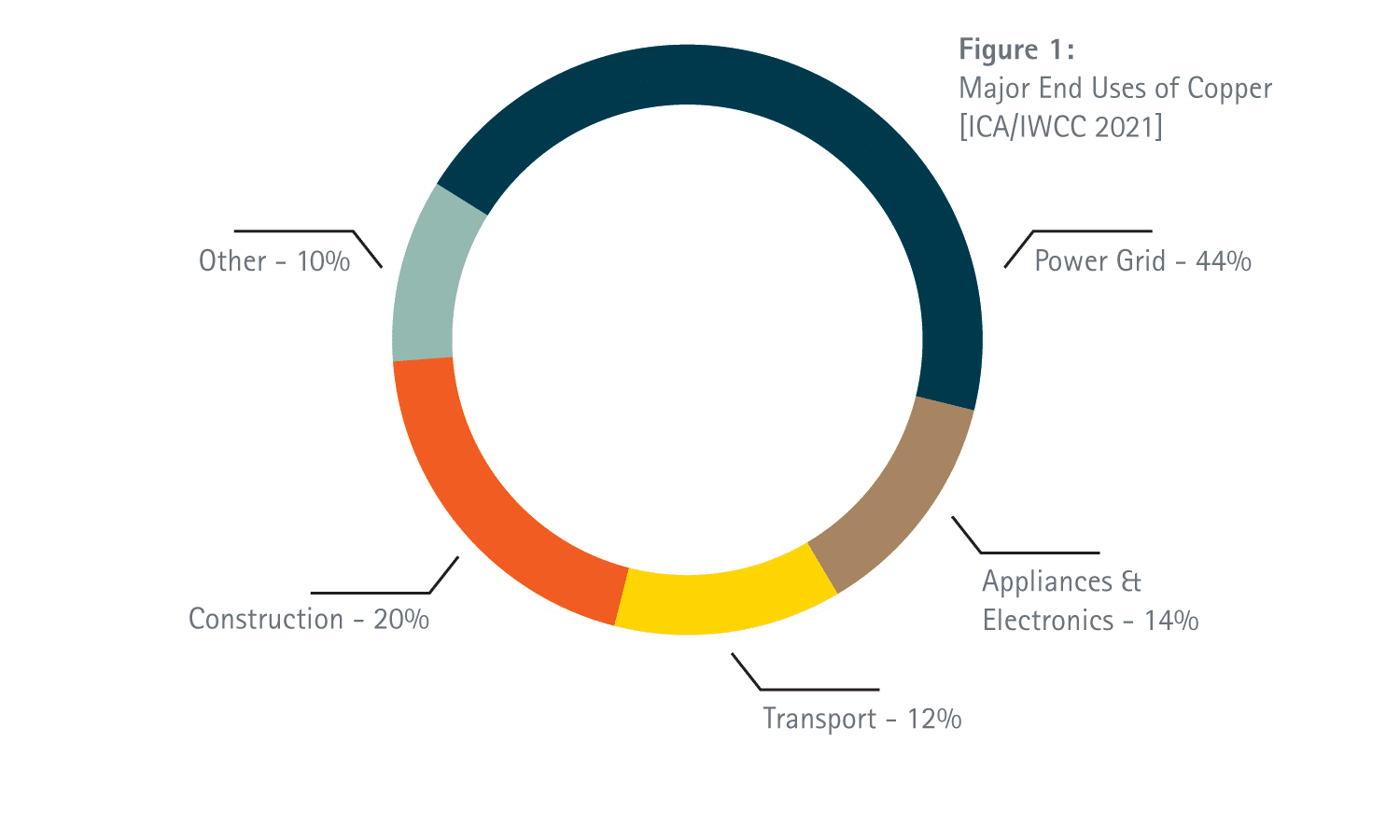

Major End Uses of Copper [ICA/IWCC]

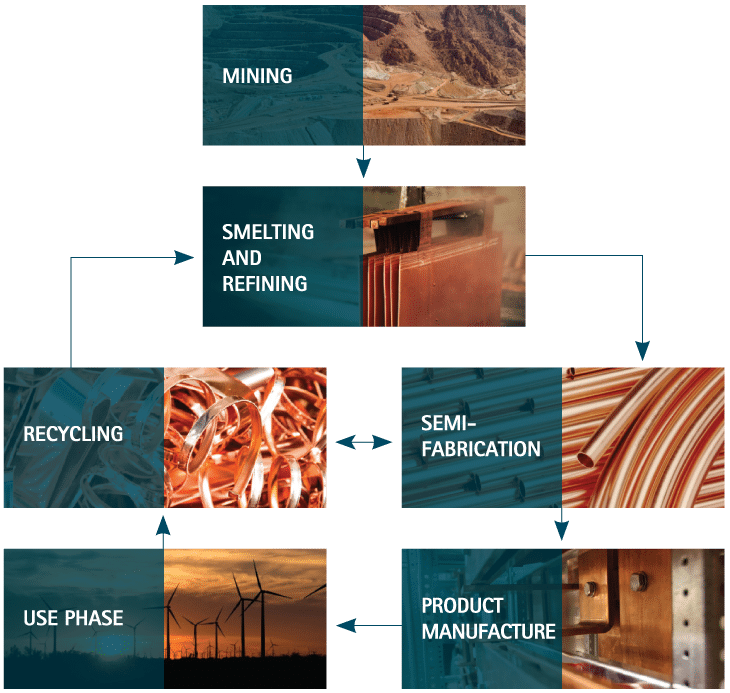

Copper Life Cycle

Schematic Illustration of Copper Cathode Production

Relative Results for Copper Cathode, by Category

Copper Environmental Profile PDF

From its original home in the earth’s crust to its long life in a finished product, such as electronics, cables, wire and tubes, copper passes through several stages.

The material produced from ores and concentrates is referred to as primary copper production. Secondary copper can also be produced by recycling scrap, as well as finished products, and has the same performance properties as primary material.